Acoustic and vibration isolation in rail traffic

Elastic bearings made of polyurethane

Elastic bearings made of polyurethane

KRAIBURG PuraSys, as part of the KRAIBURG Holding, specializes in sub-ballast mats, bearings for mass-spring-systems and other special elastic supports made of polyetherurethane in the railway superstructure. KRAIBURG PuraSys has already successfully established itself on the international market through numerous projects with its PU products for solving noise and vibration problems caused by rail traffic. KRAIBURG PuraSys is of course ISO 9001 certified and thus guarantees high quality and complete traceability of its products. PuraSys PU elements are tested according to DIN 45673-5, DIN 45673-7 and other national as well as international standards. Quality products – produced in harmony with nature Environmental protection is a key strategic task at KRAIBURG PuraSys. We are fully aware that sustainable growth is only possible if we live up to our commitments and responsibility for environmental protection. That is why KRAIBURG PuraSys has a consistent course here: environmental protection is our daily program!

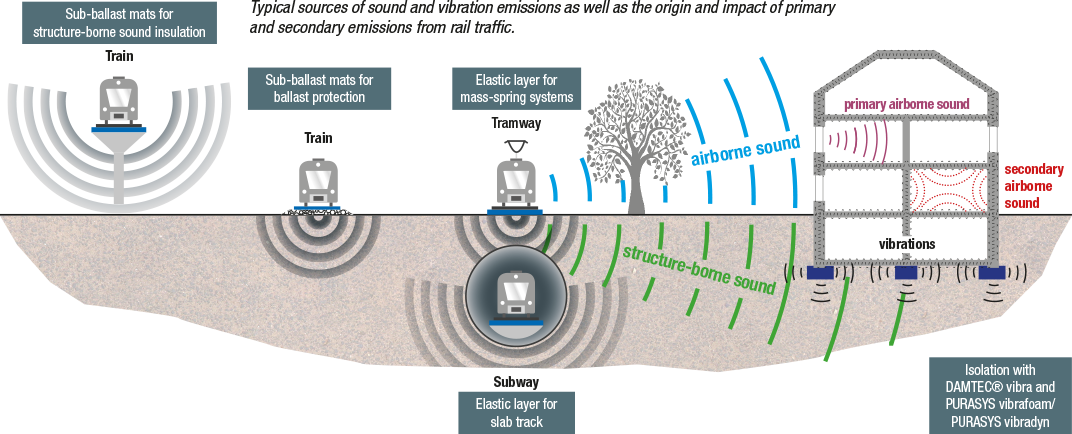

Railway vehicles generate rolling noises and vibrations during operation. This is due to roughness and imbalances on both the wheels and the rail running surfaces. Surface defects such as head checks, corrugations and slip waves on the rails are known to be among the most common sources of interference. These vibrations are transmitted to the ground via the roadway and spread as structure-borne noise. If buildings are located along or near the track, a transfer is also carried out via their foundations. The buildings begin to vibrate and, with the appropriate intensity, they are also preceived by humans as perceptible vibration or disturbing noise. Another consequence of this transmission chain is the emission of vibrations from building parts, e. g. ceilings and walls, to the environment. This takes place via the air, which begins to vibrate itself and then become audible as socalled secondary airborne sound.

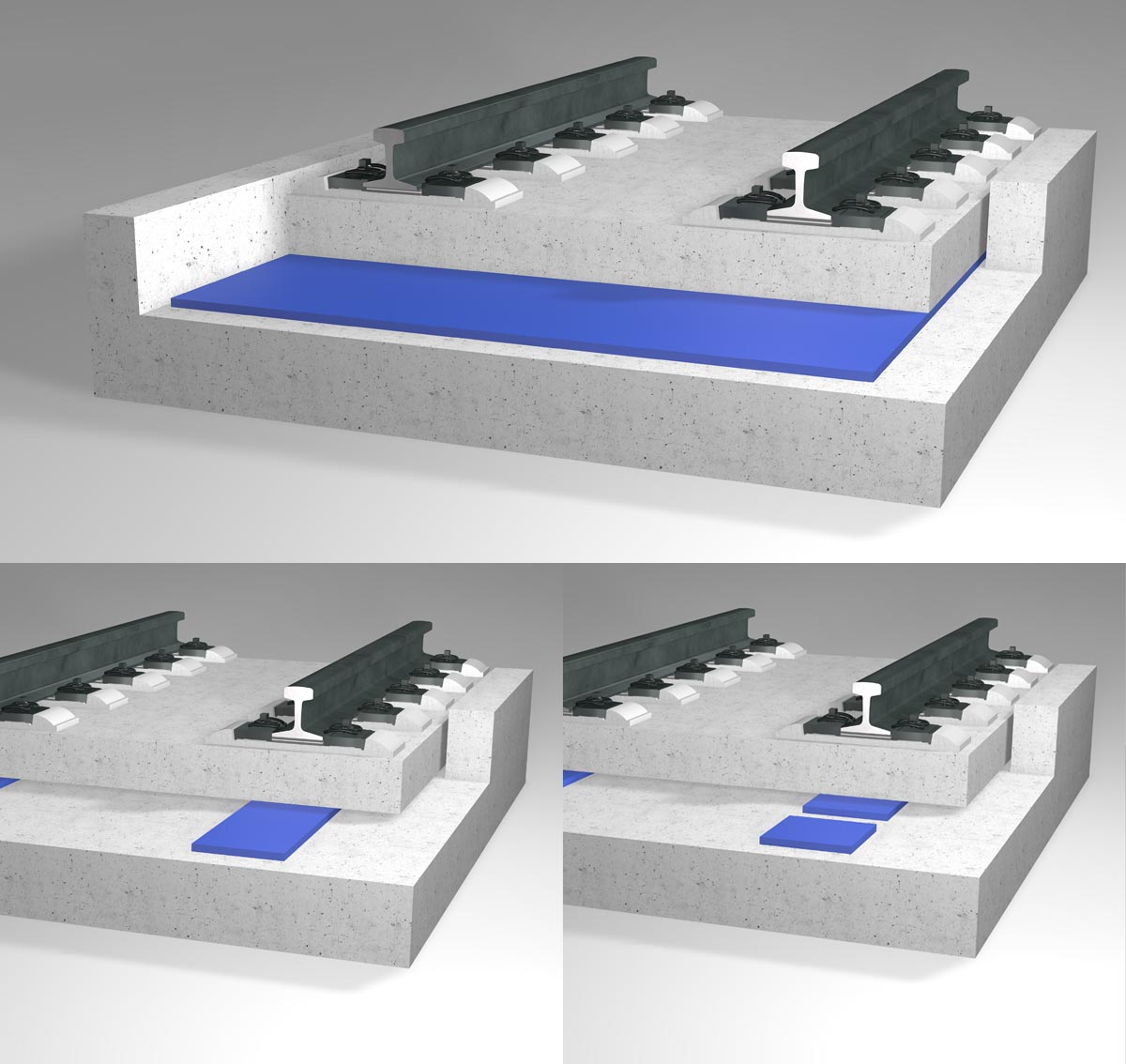

Full surface bearings, strip-like support and point bearings for mass-spring systems PURASYS MSS products are decoupling and protective mats under rail systems tested according to DIN 45673-7 (Mechanical vibration – Elastic elements of the superstructure of railway tracks). They reduce structure-borne and secondary airborne noise and vibration emissions when used in slab track (massspring system).

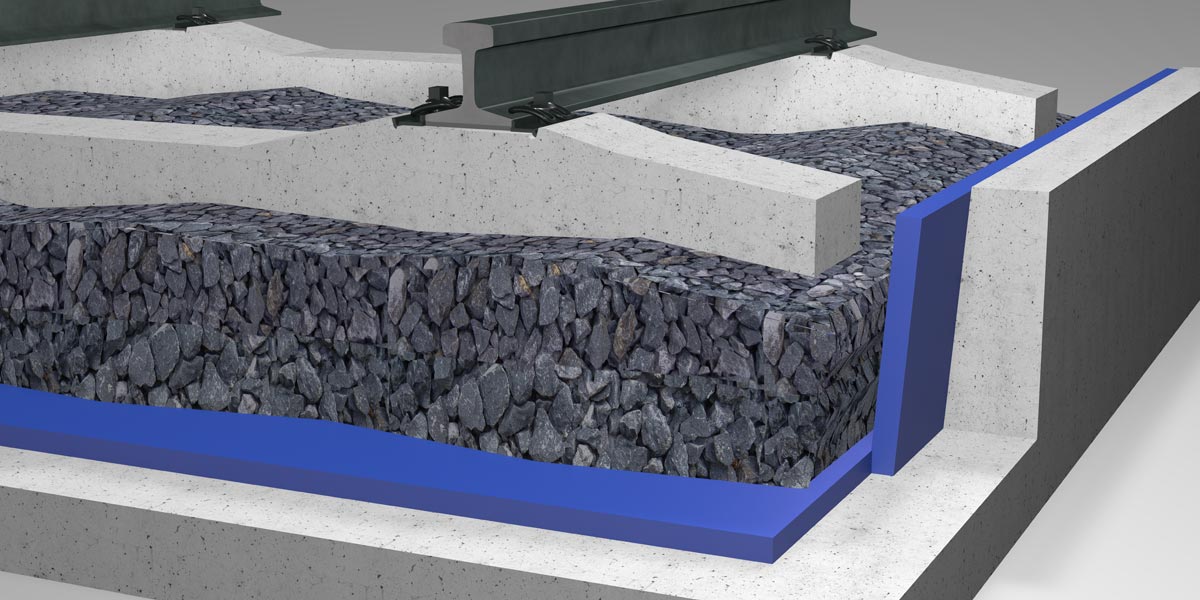

Sub-ballast mats PURASYS SBM products are decoupling and protective mats under rail systems tested according to DIN 45673-5 (Mechanical vibration – Elastic elements of the superstructure of railway tracks). They reduce structure-borne noise and secondary airborne sound as well as vibration emissions. For ballasted tracks, the service life is extended by a lower and more even load. At the same time, it can protect engineering structures or sealings.

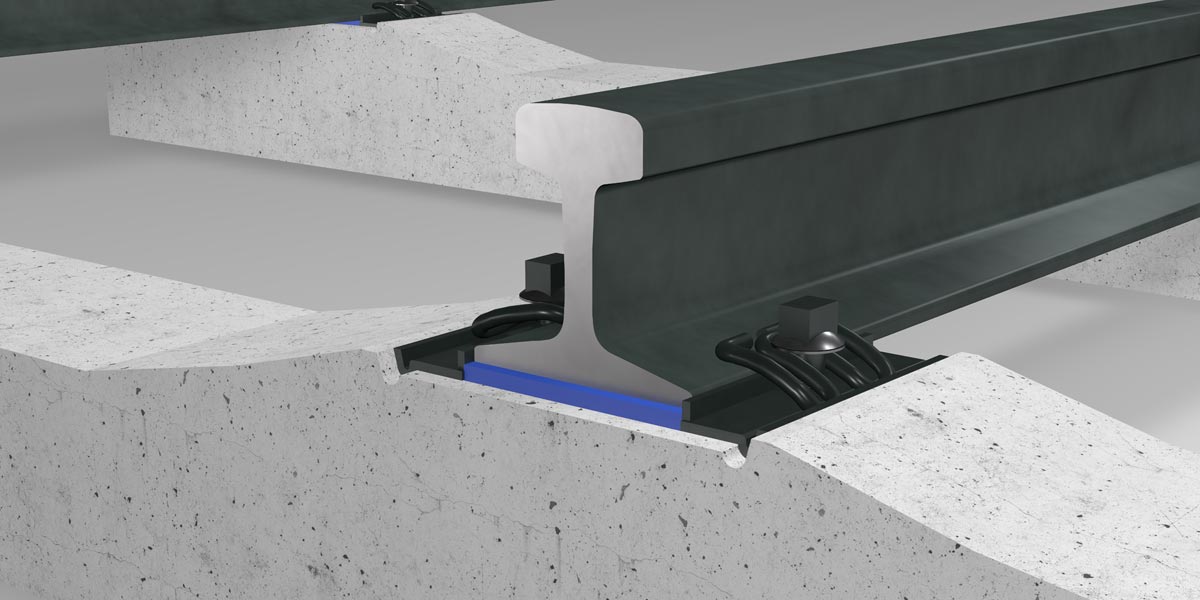

Base plate pads PURASYS BPP products are intermediate plates that increase the elasticity of the rail superstructure. The rails are decoupled from the ground and the high dynamic forces acting on the rail and fastening system are reduced.

Elastic rail pads PURASYS ERP products are intermediate layers to reduce vibrations and forces in the track superstructure.

PURASYS products for track construction are made of high-quality elastomer materials. With the extensively tested formulations, the products meet special requirements resulting from the loads in the track area. PURASYS products are produced in the form of mats and stamped or water cutted parts and are therefore suitable for point bearings, strip-like support or full-surface bearings. These elastomer materials are also used in other demanding areas such as building and tunnel construction. Particularly noteworthy is the long-term behaviour, which guarantees a constant high level of effectiveness over decades. In this way, they efficiently counteract the multi-frequency vibrations and shocks that are transmitted to the environment.

Let us convince you of the outstanding properties of our products:

![]()

protect the sensitive sealing layer against damage from ballast stones

![]()

protect adjacent buildings by reducing vibrations

![]()

uncomplicated installation

![]()

reduce the transmission of structure-borne sound

![]()

extremely durable

![]()

reduce secondary airborne sound

![]()

extend the service life of the ballast

![]()

long term stability for track position

![]()

environmentally friendly

![]()

reduction of track maintenance costs

![]()

low water absorption

![]()

extremely economical

We support you with the entire railway project

Our experience and our know-how with products for vibration reduction are a guarantee for the solution of even very complex problems. Together with you, our specialists will develop effective systems to eliminate or minimize disruptive factors in the problem areas.

To find out how effective measures can be in dealing with an emission problem, you don‘t have to wait until they are implemented. After a first inspection and analysis of the conditions on site, our specialists are able to create a calculation model in which all relevant factors regarding vibration and damping behaviour with different material properties are taken into account. This results in a realistic simulation that allows fine-tuning of these factors and enables our specialists to develop the optimum solution. At the end of the planning phase, you will receive proof of the expected effectiveness of the system. This efficacy prognosis gives you the assurance in advance that your expectations will be met successfully.

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.